Digital tools are no longer just a ‘nice-to-have’ in supply chain procurement; they’re essential drivers reshaping businesses’ operations. Traditionally reliant on manual operations, Procurement and supply chain management now use digital solutions’ power to streamline processes and enhance profitability.

According to insights from Gartner, bringing Digital Transformation into the supply chain can lead to a 20% increase in revenue and a 50% reduction in process costs. These figures aren’t just numbers; they paint a picture of a future where digital integration isn’t a luxury—it’s a necessity for maintaining a competitive edge.

Procurement, which was conventionally viewed as the simple acquisition of goods and services, now finds itself in the vanguard of this digital shift. Rather than operating in isolation, it’s deeply interconnected with the vast and intricate web of a company’s supply chain strategy. Digital adoption is a catalyst that digitally innovates every phase, from sourcing raw materials to product delivery.

Let’s decode the intricacies of Procurement, delve into the expansive domain of supply chain management, and highlight the transformative impact of Digital Adoption Platforms and tools.

Our goal? To guide professionals in understanding the future landscape where digital tools aren’t just supportive and integral to software value realization and effective supply chain strategy.

What is Procurement?

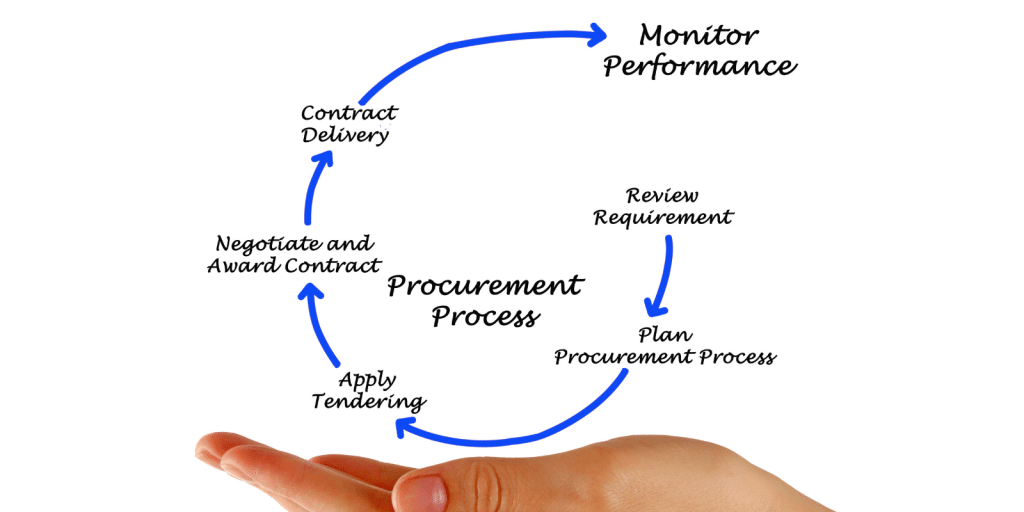

Procurement is a complex business function that involves finding, acquiring, and purchasing goods and services from external vendors, which can be a single supplier or multiple sources.

Despite the seemingly straightforward nature of the process, Procurement requires a delicate balance of strategy, negotiation, and analysis to ensure success.

Purpose and Importance: At its heart, Procurement serves multiple purposes:

- Cost Efficiency: Procurement ensures businesses remain competitive and profitable by securing the best price for goods and services.

- Quality Control: Through careful selection of vendors and suppliers, Procurement maintains the standard and quality of the products or services acquired.

- Risk Management: Procurement is pivotal in risk assessment, considering factors like vendor reliability, geopolitical issues, or market volatility.

- Evolution of Procurement: From paper-based purchase orders in the past to today’s digital procurement platforms, this function has undergone a transformative journey. With globalization and technological advancements, procurement strategies have evolved to be more collaborative, data-driven, and focused on long-term partnerships rather than short-term gains.

As we transition into an era where digital tools are most important, understanding Procurement’s intricacies becomes even more crucial. It is the foundation upon which advanced strategies, like supply chain management, are built.

Types of Procurement

While seemingly a singular function, Procurement manifests in various forms, each tailored to meet specific business needs and objectives. Understanding these types is pivotal for businesses to determine the most effective strategy for their operations. Here are some of the primary types of Procurement:

- Direct Procurement: This refers to acquiring raw materials and goods that directly enter the production process. It’s crucial for manufacturing companies where timely availability and quality of materials determine the final product’s quality.

- Indirect Procurement: Unlike direct Procurement, this involves obtaining services or goods required for day-to-day operations, such as office supplies, furniture, or IT services. These don’t directly contribute to the production process but are vital for the organization’s smooth functioning.

- Services Procurement: This focuses on the sourcing of expert services. Whether it’s legal counsel, consulting, or IT services, businesses rely on this type of Procurement to access specialized expertise that isn’t inherently available within the organization.

- Global Procurement: As businesses expand and globalization accelerates, sourcing materials and services from international suppliers becomes essential. This procurement type necessitates understanding global markets, tariffs, geopolitical considerations, and cultural nuances.

- e-Procurement: Harnessing the power of the internet and digital tools, e-procurement streamlines processes by automating purchase orders, invoicing, and supplier management. As highlighted in our introduction, this form of Procurement is becoming increasingly prevalent, marking the intersection of digital adoption and procurement strategy.

What is a Supply Chain?

A supply chain is a network of interconnected steps, processes, and stakeholders involved in creating and delivering a product or service to the end consumer. Each entity plays a specific role, ensuring the seamless flow of goods and services, from the raw material suppliers to manufacturers, from distributors to retailers.

Components of a Supply Chain

- Suppliers: Suppliers are Entities responsible for producing raw materials or components required for the product.

- Manufacturers: They convert the raw materials into the final product. In larger setups, this might involve multiple stages of manufacturing.

- Warehousing: Manufacturers typically store products in warehouses until they are ready to distribute them.

- Distribution: This involves transporting the product to various retailers or consumers.

- Retailers: The final step before a product reaches the consumer. Retailers could be physical stores or online platforms.

- Customers: The end goal of every supply chain. Meeting the needs and expectations of customers ensures business success.

However, it’s not just about moving products. A modern supply chain is also about the flow of information, finances, and integrated planning. With the digital era upon us, introducing and adapting digital tools are vital.

More than two-thirds of respondents expect digitizing their supply chain to require some upskilling of employees. Yet, the challenge arose when only 7% said digital upskilling was their top priority. This gap signifies the importance yet lack of readiness many face in adapting to a digitized supply chain.

Moreover, as businesses strive for sustainable operations, integrating ESG (Environmental, Social, and Governance) criteria into supply chains has become crucial. However, challenges persist. A lack of digital skills among employees (80%) and the availability of data and digital tools (73%) are prominent barriers to effectively integrating ESG into company supply chains.

In essence, a supply chain isn’t just a logistical framework but a strategic tool that, when optimized and digitized, can significantly enhance business operations and align with modern-day priorities and challenges.

Read More: Demystifying Supply Chain Management: How to Implement an SCM Training Plan

Differences Between Procurement and Supply Chain Management

Businesses distinguish between “procurement” and “supply chain management” (SCM) as two separate concepts, even though they are interchangeable. Both are essential to the efficient functioning of an organization, but they cater to different aspects of the operation. Here are the key differences:

| Criteria | Procurement | Supply Chain Management |

| Scope of Operation | Focuses on sourcing and obtaining goods or services from external vendors. Involves vendor selection, negotiation, contract management, and payment processes. | Encompasses the sourcing of raw materials to delivering the final product to the consumer. Integrates processes like procurement, production, distribution, and logistics. |

| Primary Objective | Ensure that the organization acquires necessary goods and services at the best possible price while ensuring quality and timely delivery. | Aims for a seamless flow of goods, information, and finances across the entire chain, optimizing operations and enhancing customer satisfaction. |

| Stakeholder Engagement | Engages directly with suppliers and vendors to foster relationships for beneficial terms and conditions. | Engages with a broader range of stakeholders, including suppliers, manufacturers, logistics providers, and retailers. |

| Strategic Focus | Concerned with cost-saving, risk management, and supplier relationship management. | Focuses on broader strategy aspects such as inventory management, demand forecasting, and overall operational efficiency. |

| Integration of Digital Tools | Primarily involves e-procurement systems for automating purchase orders and supplier management. | Holistically addresses various components through tools like inventory management systems and advanced analytics for demand forecasting. |

Understanding Supply Chain Procurement

While a component of the broader supply chain, supply chain procurement plays a pivotal role in determining the system’s efficiency, cost-effectiveness, and responsiveness. At its essence, it refers to obtaining and managing the essential goods and services that fuel an organization’s supply chain operations.

Key Aspects of Supply Chain Procurement

- Strategic Sourcing: Beyond just acquiring goods, strategic sourcing involves evaluating and selecting suppliers based on cost, quality, reliability, and capacity. It’s about building lasting relationships with vendors that align with an organization’s long-term goals.

- Demand Forecasting: Accurately predicting the demand for goods ensures that procurement professionals can place timely orders, avoiding stockouts or overstock situations.

- Supplier Relationship Management (SRM): Just as CRM focuses on customers, SRM fosters and maintains strong, mutually beneficial relationships with suppliers. A robust SRM strategy can improve negotiation terms, quality, and innovations.

- Cost Management: A core objective of Procurement is to acquire goods at optimal prices. This doesn’t mean always choosing the cheapest option but balancing cost, quality, and service.

- Risk Management: To effectively mitigate risks in supply chains, companies must identify potential issues and develop strategies to address them. This proactive approach can help minimize the impact of geopolitical problems and natural disasters on procurement processes.

- Integration with Technology: As the broader supply chain digitizes, Procurement isn’t left behind. Utilizing digital tools can automate repetitive tasks, provide insights through analytics, and enhance vendor management.

However, there’s a significant gap in expectation vs. realization. Only 17% of executives say their company’s investments in supply chain technology have fully delivered the expected results, emphasizing the need for strategic and well-informed digital adoption.

Supply chain procurement delves deeper than conventional Procurement, adding layers of complexity and strategy. With globalization, companies source from and cater to global markets, necessitating a robust system to manage relationships, logistics, contracts, and risk mitigation. According to a survey, digital Procurement can accelerate transaction processing by up to 30%.

The Game-Changing Role of Digital Tools in Supply Chain Procurement

In the age of digital disruption, Procurement is undergoing a paradigm shift. As businesses vie for a competitive advantage, the role of technology has transcended from being an operational aid to a strategic enabler.

Let’s unpack the transformative influence of digital tools in the domain of supply chain procurement:

- Enhanced Visibility: With tools like Internet of Things (IoT) sensors and advanced analytics, businesses gain real-time insights into their supply chain. This transparency enables proactive decision-making, from adjusting inventory levels to anticipating supply chain disruptions.

- Automated Workflows: Robotic Process Automation (RPA) and Artificial Intelligence (AI) are automating routine procurement tasks, from purchase order creation to supplier invoice reconciliation. This automation reduces errors and frees up professionals to focus on strategic initiatives.

- Strategic Supplier Relationships: Supplier portals and e-procurement platforms foster better supplier communication and collaboration. Features like instant messaging, shared dashboards, and contract management modules streamline interactions and build trust.

- Predictive Analytics: Advanced algorithms can forecast demand, assess supplier performance, and predict potential supply chain disruptions. These insights empower businesses to make informed, data-driven decisions.

- Sustainability and Compliance: Digital tools provide a granular view of the supply chain, enabling businesses to ensure compliance with regulations, track the sustainability of their operations, and even integrate ESG (Environmental, Social, and Governance) factors.

- Challenges and Realities: While the promise of Digital Transformation is immense, its actualization isn’t straightforward.

Integrating digital tools demands a cohesive strategy, proper implementation, and continuous upskilling. The embrace of digital tools has revolutionized traditional supply chain procurement methods. Now, data-driven insights guide decisions, AI predicts market shifts and digital platforms foster collaboration across borders.

The result? Enhanced efficiency, cost savings, and a competitive advantage.

Moreover, Gartner states that at least 50% of large global companies will use AI, advanced analytics, and IoT in their supply chain operations.

These digital solutions significantly impact the future of supply chain procurement. However, businesses must approach this digital journey with a clear strategy, considering the immense potential benefits and the challenges in actualizing them.

Digital Adoption: The Future of Procurement

Digital Transformation has shifted to the forefront for supply chain leaders in recent years. With investment in digitalization forecasted to grow 16.5% (up to $6.3 trillion) over the next two years, business leaders must prioritize digital strategies to stay competitive.

Integrating digital solutions enhances the immediate operational benefits, long-term strategic growth, and resilience of supply chains that are becoming increasingly sophisticated and global.

Over the next two years, businesses will have clear objectives regarding their supply chain tech endeavors. A significant 53% focus on leveraging these technologies to drive growth, while an equal proportion, 51%, are targeting cost optimization. These statistics are not mere ambitions but strategic directions revealing the weightage organizations place on digital adoption within Procurement.

Key Strategic Priorities:

- Data-driven Decision Making: With increasing data volumes, businesses invest in advanced analytics tools that provide actionable insights, helping refine procurement strategies and decisions.

- Sustainability: Beyond profit, the modern supply chain places immense value on sustainable and ethical practices. Digital platforms assist in tracking and ensuring sustainability across the procurement process.

- Supplier Collaboration: Promoting robust supplier relationships is important in a connected digital era. Digital platforms enable seamless communication, real-time feedback, and collaborative problem-solving solutions.

- Continuous Learning & Upskilling: As digital tools evolve, so does the need for upskilling. More than two-thirds of respondents believe that digitizing their supply chain necessitates some upskilling of employees. Maintaining a workforce adept at leveraging the latest digital tools to their fullest potential is essential.

- Risk Mitigation: Advanced digital tools provide predictive insights, allowing businesses to effectively preempt potential disruptions and strategize mitigation plans.

- Achieving ROI on Digital Investments: While digital adoption promises numerous advantages, realizing a tangible ROI remains challenging. A holistic digital integration approach, realistic expectations, and continuous review are crucial.

Digital Adoption in Procurement is not a fleeting trend; it’s a fundamental shift in how businesses visualize and strategize their procurement processes. As the landscape evolves, companies that effectively use the power of digital tools, keeping in line with their strategic objectives of growth and cost optimization, will position themselves at the forefront of industry innovation.

The wave of digital adoption is reshaping industries, with Procurement being no exception. Digital adoption platforms (DAPs) are emerging as crucial enablers in this transformation, offering tailored guidance and facilitating seamless transitions into new software environments.

Why are Digital Adoption Platforms Pivotal?

| Feature | DAPs Significance |

|---|---|

| Real-time Data Visibility and Access | Provides instant access to essential information, ensuring decisions are based on the most current data. |

| Built-in Agility | Enables businesses to quickly adapt to new software environments or market changes, ensuring responsiveness and competitiveness. |

| Advanced Predictive Analytics | Forecasts trends, identifies challenges, and offers actionable recommendations based on software utilization insights. |

| Automated Workflow Orchestration | Streamlines processes by automating routine tasks, reducing manual interventions and the potential for errors. |

| Collaboration Across the Value Chain | Facilitates seamless interaction between all stakeholders in the procurement process, ensuring alignment and information flow. |

| Guided Workflows | Offers real-time, context-sensitive guidance to users, ensuring tasks are executed precisely and efficiently. |

| Training and Onboarding | Provides a seamless onboarding experience, accelerating the familiarity of new employees with software tools and reducing the learning curve. |

| Reduced Support Costs | Decreases reliance on IT support through real-time guidance and automated processes, leading to cost savings. |

| Software Value Realization | Ensures maximum utility of every software feature, optimizing return on software investments. |

Read More: A Comprehensive Guide to Effective Supply Chain Management Training Through Software Adoption

Benefits of Digital adoption in Procurement

- Enhanced Decision-making: As businesses increasingly adopt digital tools, the abundance of real-time data at their fingertips paves the way for more informed and strategic decision-making. Gone are the days of relying solely on intuition. Now, empirical evidence guides the procurement process, reducing risks and optimizing outcomes.

- Streamlined Operations: Companies are replacing once complex manual, paper-based processes with digital workflows. These digital pathways expedite tasks and reduce human error, ensuring the procurement process is more efficient and accurate.

- Robust Vendor Relationships: Digital platforms offer a transparent and collaborative environment. This transparency fosters trust between organizations and their vendors, leading to more powerful, more productive relationships. Clear communication channels reduce misunderstandings and improve collaboration.

- Sustainable Procurement: By integrating digital tools, businesses can align their procurement strategies with environmental, social, and governance (ESG) goals. As mentioned earlier, 80% of companies cite a lack of digital skills among employees as a challenge to integrating ESG into supply chains. But with proper digital adoption, companies can effectively address these challenges.

- Increased ROI: Investing in digital tools for Procurement isn’t just about streamlining processes. It’s about realizing genuine returns on those investments. Digital adoption platforms, in particular, play a pivotal role in software value realization. Organizations should utilize every feature of their software solutions to maximize their ROI.

- Future-proofing: The world of Procurement is not static. New challenges and opportunities arise regularly. By weaving Digital Adoption into the fabric of their procurement strategy, organizations address present challenges and equip themselves to adapt to future shifts in the landscape.

Relevant Read: Digital Adoption’s Impact on Supply Chain Efficiency

The Apty Edge in Supply Chain Procurement

The momentum of the digital age is undeniable. As businesses strive to navigate the complexities of supply chain procurement, the right digital adoption tools can spell the difference between stagnation and transformative growth. It’s not just about integrating technology; it’s about using the right solutions that provide actionable insights, facilitate real-time decision-making, and enhance collaborative efforts across the value chain.

Positioned at the forefront of Digital Adoption Platforms, Apty understands the nuances of software adoption, value realization, and metrics-driven process implementation. Apty offers a holistic solution to the challenges of modern-day supply chain management. Their platform is more than just a tool—it’s a strategic partner ensuring successful software launches, efficient SCM implementation, and game-changing updates.

Apty doesn’t merely offer a platform; it brings a transformative approach to supply chain procurement. With features that optimize workflow orchestration, ensure real-time data visibility, and promote collaboration across the value chain, Apty actively bridges the gap between technological potential and tangible outcomes. Its advanced predictive analytics give businesses foresight, enabling them to make proactive decisions and prevent potential supply chain disruptions.

According to a survey, accelerating procurement Digital Transformation is the top priority for 45% of procurement leaders. As businesses transition towards this goal, aligning with industry leaders like Apty is paramount. After all, in a world where technology continually evolves, having an expert by your side ensures survival and dominant leadership.

Procurement deals with the acquisition of goods and services. Supply chain management, on the other hand, includes a broader scope of sourcing, manufacturing, logistics, and distribution.

Digital transformation enhances supply chain procurement by streamlining operations, enabling real-time data visibility, and reducing costs. It’s pivotal for staying competitive in today’s digital age.

Apty’s Digital Adoption Platform (DAP) provides features like automated workflows, predictive analytics, and actionable insights. This enables more efficient, data-driven decisions in supply chain management.

Accelerating digital transformation is key for procurement leaders because it drives operational efficiency, optimizes costs, and ensures long-term sustainability and competitiveness.